Yet Another Primer on the Electronics Industry

August 18, 2022

The what, why, why now and what next of Luminovo: read our vision and plans for the future after receiving €11M in Seed funding.

In A short primer on the electronics industry we gave the briefest of overviews of the stakeholders in the electronics industry and why we are excited about building software for that industry.

That excitement hasn’t waned and today we are just as excited to announce a new injection of capital and welcome some new members to the Luminovo family (see more here).

If you are still a little confused about the problem we are trying to solve at Luminovo (just like most of our friends and all of our parents before you) and why in the world anyone would give us this much money to tackle it: this post is for you.

And fret not, you are not alone. Despite the omnipresence of its outputs, developing and manufacturing electronics is an opaque process that happens behind-the-scenes for most people. At Luminovo, we are helping to re-imagine exactly that opaque process from design to manufacturing, making it faster, cheaper and more reliable. If we succeed, most of your friends still won’t know more about that process (or how we made it better), but they will feel its impact on a daily basis. They already do today.

If you start counting the electronic devices you interact with in your everyday life, you will be at it for a while. Your laptop, your smart phone, your fridge, your door bell, your bluetooth speakers, your car, your WiFi router, your AC, the satellites for your GPS signal, the X-ray machine at your last doctor’s appointment. If you keep counting and keep counting for your neighbors too, you’ll end up with an unfathomably large number. The value of all electronic products produced in just one year (the market size of the electronics industry) is measured in trillions–a number with 12 zeros–of dollars.

And not only is the electronics industry big and important, its entire supply chain is currently undergoing a tectonic shift from email, Excel and on-premise software to automation and collaboration software in the cloud. Whenever that happens to an industry that size, paying close attention tends to pay off well.

So let’s get specific. The shortest “what we do at Luminovo”-explanation we currently have to offer is: we help the developers of electronic products automate collaboration with their manufacturers. But what do these people need to collaborate on in the first place? And why is automating that collaboration an important problem to work on?

The what

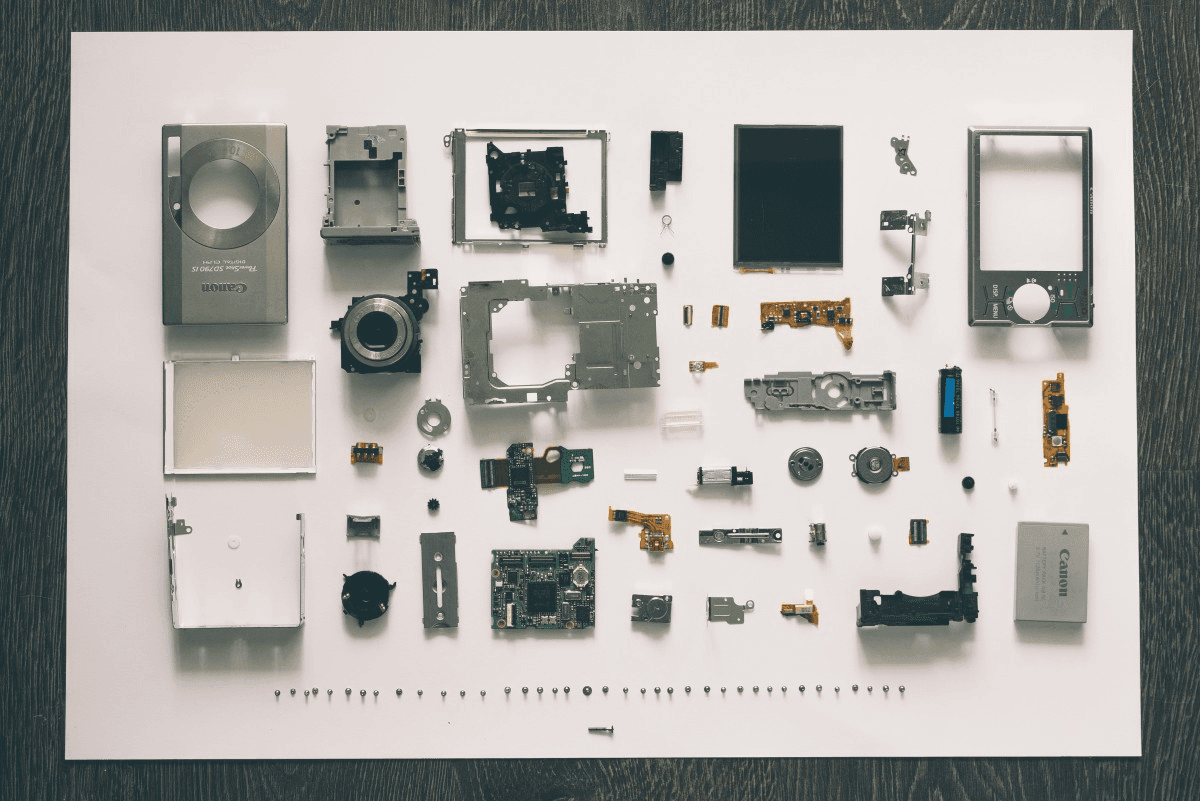

To understand where collaboration is needed during the design and manufacturing of an electronic product, it’s helpful to visualize taking a product apart into all of its components.

You will end up with a long list of parts (called the Bill of Materials) that can be divided into two categories:

off-the-shelf parts (like resistors, chips, diodes, screws etc.) that someone else designed and that you can buy at the manufacturer or a distributor “off the shelf”;

made-to-specification parts (like a printed circuit board or mechanical parts like a piece of metal, plastic or glass) that you designed and need to procure from a specialized manufacturer.

The complexity of a printed circuit board (PCB) and the sheer amount (we are talking hundreds of millions) of available electronic off-the-shelf parts is what makes the design and manufacturing of electronics different (and arguably more complex) than other hardware products without electronics (like a wooden chair).

Once you have chosen, designed and procured all of these parts, all that’s left to do is to assemble them according to your design. Parts of this assembly process are done with robots (check out this video here to see a pick and place machine in action) and other parts with humans (video here).

Sounds easy, but unfortunately you need to do all of this while keeping the following variables under control.

Technical feasibility

Will the finished product actually work? Will it do what I want it to do?

Can I actually manufacture the PCB like that? What about my other made-to-specification parts?

Can I actually assemble the final product?

Cost

What do all the off-the-shelf parts cost?

What does manufacturing the printed circuit board cost? What about my other made-to-specification parts?

What will assembly cost?

Availability

Who still has the off-the-shelf parts in stock? Distributors? Manufacturers?

How much longer will the part manufacturer produce them?

In case you are wondering why we didn’t mention the availability of made-to-specification parts here, it’s because the supply chain risk is usually dominated by off-the-shelf parts. If the manufacturer of your made-to-specification part goes out of business, you simply send the design of that part to a different one. If the manufacturer of your off-the-shelf part goes out of business (or decides to no longer produce your part), you’ll have to toil to find an alternative (with the same fit, form and function) or suffer the consequences (re-design your product). Adapting supply to demand is also much harder for electronic off-the-shelf parts (building a new semiconductor factory takes years and then more time to ramp to good yields).

Compliance & ESG

Is each of the off-the-shelf parts I chose compliant with the relevant regulations? What about the final assembly?

What is the carbon footprint of the products and services involved? How can I minimize it?

Unfortunately, the knowledge to answer all of these questions does not fit into a single head and is usually spread across different people working in different departments and often different companies.

The why

The many stakeholders involved in the design and manufacturing of an electronic product lead to endless hand-offs (often done via email and Excel). Those hand-offs lead to waterfall processes and long feedback loops, that lead to mistakes, delays and rework.

We want to help get rid of those hand-offs. We want better collaboration and shorter feedback cycles. But why?

Mistakes, delays, and rework are annoying in and of themselves, but we believe that better collaboration and shorter feedback loops aren’t just about saving time (and costs) in existing workflows. It can help change the way we develop electronics in the first place.

Time to borrow some credibility from other people and other industries.

“When people are required to jump through hoops, all sorts of bad things might happen, some of them surprising. One of the least surprising is that many people stop jumping.” — Cass R. Sunstein, Sludge

Slow feedback doesn’t just waste time. It changes behaviors. And so does fast feedback. When digital photography first emerged, it didn’t just speed up the way we developed photos. It changed the way we take them. We play around. We experiment. Video editing software or WYSIWG editors are similar examples. In Thinking Fast and Slow, Kahneman describes fast feedback loops as a key to building up expert intuitions. In “Inventing on principle”, Bret Victor expounds on the same principle in different words: “Creators need an immediate connection to what they’re creating.”

All to say: If we can bring shorter feedback loops to the electronics industry, the electronics industry will bring better electronic products to us. They will be able to experiment more and iterate quicker. And better electronic products means better medical devices. Safer cars. Cheaper phones. New things we haven’t even thought of yet.

Now that we’ve discussed the importance of shorter feedback cycles, it feels appropriate to revisit our “what we do at Luminovo”-explanation (we help the developers of electronic products automate collaboration with their manufacturers) and make an important note: collaboration is not just communication. Or in other words: we are not just trying to build a chat tool that helps developers and manufacturers to talk to each other. They talk to each other plenty as of today. When we are speaking about better ways to collaborate, we are mostly speaking about ways to remove the need for them to talk to each other in the first place. This can be done by automatically providing the feedback you’d get from speaking to your manufacturer as well as by providing ways to resolve design and manufacturing issues together asynchronously.

The why now

2022 is a good time to be building a software startup for the electronics industry.

The industry as a whole keeps growing in importance year-by-year (think electronic vehicles, think internet-of-things).

There are many industry-wide trends we can piggyback on: an unparalleled move to the cloud fueled by the pandemic-induced needs of working from home; an increased adoption of APIs by suppliers of electronic parts ushering in a new generation of software tools geared for automation; a worsening skilled labor shortage leading to increased demand for tools that can conserve and disperse expert knowledge; a global chip shortage increasing pressures around supply chain transparency and agility.

And we are not stopping there, but setting new trends ourselves: going API-first for the analysis and costing of printed circuit boards; moving the complexities of calculating the costs of the electronics assembly process from Excel sheets to cloud software; enabling a shift from “designing for manufacturing” to “designing with manufacturing” by connecting all stakeholders involved in bringing electronic products to life on one platform.

The what next

The way it works today, you can liken designing electronic products to driving a car… blindfolded. You feel the bumps in the road and you will know if you crash. But it’s hard to see where you are going and how your actions influence your outcomes. At Luminovo, we want to help the electronics industry take off its blindfolds. (Lumi… novo… new light… get it?!).

We started just two years ago. Today, we already help more than fifty electronics manufacturers all over Europe automate their processes around material and manufacturing costing. With us, they monitor their Bills of Materials for cost, compliance and availability issues and enable asynchronous collaboration between developers, procurement, suppliers and manufacturers.

And that is only the beginning. We set ourselves the goal to touch one million electronic products with our software by 2025. Our roadmap for the next year is ambitious, we have new money in the bank and are growing fast. If you want to join us for the ride, check out our website and open positions. Resistance is futile!